MENUMENU

Ring Shear Testers have been designed to do more than for providing flow ability testing, which has uses for product development or quality control.

The Shear test has been designed to assist hopper design for flow.

The online webinar will start at 10 am GMT on 11th of October, more details about the event are below and to book your place.

The test results can be used to work out hopper slope angles and outlet dimensions with the goal to achieve mass flow, and to avoid flow obstructions.

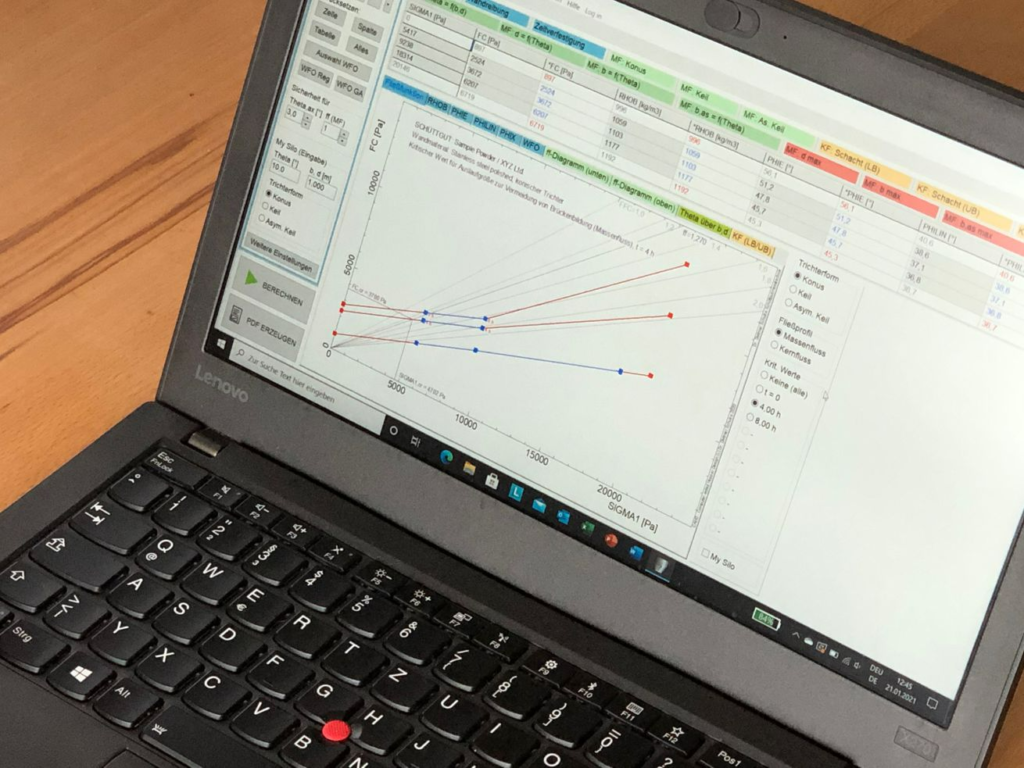

The new hopper design software imports flow properties of bulk solids measured with Schulze Ring Shear Testers by directly reading files of the RSTCONTROL software. Results obtained with other testers can be entered through a template for Microsoft EXCEL*.

The software intuitively helps the user to generate the required graphs of unconfined yield strength, bulk density, internal friction, and other important properties which are required.

Interactivity is important to allow a transparent approach and to be able to intervene in critical products to avoid errors by “stubborn” application of the design methods. Finally, the software generates a set of hopper design data such as wall inclination angles for different hopper shapes, and critical outlet dimensions to avoid cohesive arches or stable ratholes where the important effect of time consolidation is taken into account. With the new software, time-consuming iteration cycles at stress-dependent friction angles are no longer required: All stress-dependencies specified by measured data are taken into account.

Thus, e.g., the hopper slope angle required for mass flow can be specified as a function of outlet size or local hopper cross section, respectively. The results are available as a comprehensive pdf document from which all steps of the interpretation can be understood in retrospect. This is vital for a complete documentation of a hopper design. In addition to the design of mass flow silos for conical, wedge-shaped, and asymmetric wedge-shaped hoppers, taking into account the time consolidation, the design of funnel flow silos is also included. The software uses newly calculated design parameters (e. g., flow factors, ff) based on Jenike’s original differential equations published in Bulletins 108/123. However, other approaches are included and can be applied alternatively.